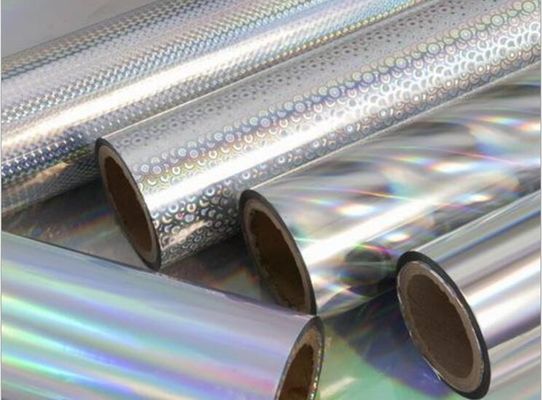

Glossy Hot Lamination Mylar Diamond Diffusion Silver Bopp Film

Product Details:

| Place of Origin: | China |

| Brand Name: | BM |

| Certification: | ISO 9001 |

| Model Number: | Metalized BOPP Film |

Payment & Shipping Terms:

| Minimum Order Quantity: | 3tons |

|---|---|

| Price: | 0.04-0.1 |

| Packaging Details: | Carton Box |

| Delivery Time: | 10 days |

| Payment Terms: | T/T, Western Union |

|

Detail Information |

|||

| Product Name: | Hot Lamination Fim | Material: | Bopp With Embossing |

|---|---|---|---|

| Usage: | Decoration And Composite Packaging | Moq: | 3tons |

| Shipping: | By Sea | Function: | Gift Packaging Or Metalized |

| High Light: | Lamination Silver Bopp Film,Silver Bopp Film,Glossy Silver Bopp Film |

||

Product Description

Transparent white glossy bopp hot lamination Mylar Diamond Diffusion film

![]()

Both laser film and laser transfer paper are inseparable from the interlocking process of laser molding, pressing laser graphics, coating, cutting, transfer, and curing. Production of laser film 1. Making laser moulding plates Making laser moulding plates is an important production link of laser film. It can be said that the casting level of the laser mold plate determines the production quality of the laser film. The casting laser mold press plate is different from the plate making in the printing process, and the requirements are also different. The laser-molded plate is made of sheet metal by electroforming. The plate has both strong hardness and flexibility. It cannot be deformed under high-temperature baking, and there are no small defects on the plate when observed under a magnifying glass. The use of the laser molded plate also needs to be careful. There should be no small collisions during the cleaning and maintenance, and no oil or water splashes on the laser molded plate; otherwise, the product will be scrapped. 2. Coating Generally, the price of laser film has two materials, one is OPP and the other is PET. The former can be directly printed on the laser graphic ticket, while the latter cannot. If you want to press the laser graphics on the PET base film, you must first coat the PET base film with a thin coating, and then press the laser graphics. The coating process should be carried out in a sealed, constant temperature and humidity environment. 3. The principle of pressing laser graphics and text is to directly press the laser mold press plate on the film substrate or coating at high temperature to form a light refraction point detection system and instrument with uneven and different sizes. The diffuse reflection of wavelength light will make the laser film appear rainbow light. Three elements of Founder force. If the control of these three elements is not accurate enough, serious chromatic aberrations, black spots, white spots, water lines, wrinkles, cloud flowers, pitting, laser graphics and light beam deformation, and tension instability will occur. Future printing will bring troubles, which will prevent the laser film from being used in printing production.